The operation of combing the wool can only take place after the stages of preparation of the wool, i.e. after shearing, washing/scouring and carding. Because yes, this step is not mandatory in the long process of wool transformation!

Some yarns are obtained from uncombed wool. After carding, which consists of aerating, untangling and opening the wool fibre in order to prepare it for the spinning stages, the fibres are either divided into rovings for spinning or into sliver for the combing stage.

Combed wool, definition

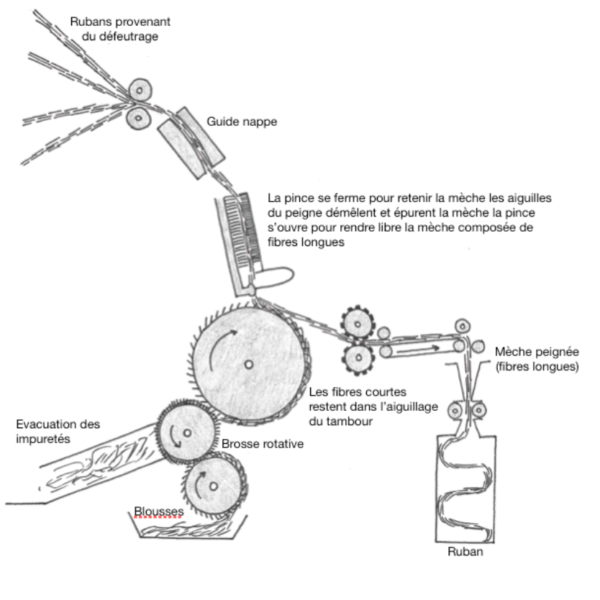

The purpose of combing wool is to remove all impurities from the wool fibres, such as the remains of vegetable matter or wool fibres that are too short, called “noils”, or wool fibres that are too tangled, called “neps”, which may have remained despite the previous carding stage.

The idea is therefore to obtain finer, stronger yarns with more demanding properties as a complement to the carding stage. During combing, up to 15% of the carded wool can be lost!

What does wool combing involve?

How does wool combing work in practice? The combing of wool consists, among other things, of passing the wool fibres through a succession of perfectly parallel and increasingly fine “combs”, which will eliminate fibres that are too short.

At the end of the combing process, a so-called combed wool sliver is obtained, which is then used by the spinning mills.

The characteristics of worsted wool

How do you recognize worsted yarn? Unlike carded yarn, which is lighter and more airy, combed yarn is more regular and dense! One of the characteristics of combed wool is that the fibre is tighter and the air trapped during carding is expelled. This means that worsted wool is less warm than carded wool, but it is stronger, which means that the garment is more resistant to wear and tear. The yarns of worsted wool are remarkably uniform, which makes it possible to produce very fine and precise knitwear and fabrics! Combed wool is often used in the luxury sector for furniture and clothing.

Combing wool is a time-consuming and tedious step, but not a mandatory part of the wool processing. However, combing does ensure a higher quality, cleanliness and purity of the carded wool. Once this stage is completed, the other processing stages take place, namely: spinning, dyeing, knitting or weaving. It all depends on the type of product you want!